| PREVIOUS PRESENTATION | BACK TO PROGRAM OVERVIEW |

THz Innovation Lab: Bringing THz technologies from lab to industry

Simon Jappe Lange1,2, Miriam Galbiati3, Thorsten Bæk1,2, Oscar Garcia Garcia1,2, Mads Ehrhorn1,2, Bjørn Mølvig1,2, Lorenza Pia Foglia1,3, Ryan Yde3, Jonas Sikorskis1, Sara L. Garcia3, Mihai Vlad Ursta Anghel1, William Vang Carstensen1, Tobias Olaf Buchmann1, Matej Sebek1, and Peter Uhd Jepsen1

1DTU Electro, Technical University of Denmark, 2800 Kongens Lyngby, Denmark

2GLAZE Technologies, Rundforbivej 23 st tv, 2950 Vedbaek, Denmark

3GLAZE Life Sciences, Birkedommervej 90, st th, 2400, Copenhagen, Denmark

Introduction

The historic “THz gap” is a concept defined to underline the difficulty in creating technologies that can generate and detect electromagnetic radiation at 0.3 to 10 THz in frequency. This has led to only a few commercial THz system offerings, which in turn has led to only a few industrial applications of THz.

We, the authors, fundamentally believe that THz has a significantly larger potential to drive positive change for industry and society in general compared to what has been demonstrated to date. We also believe that we can make a large contribution to the widespread adoption of THz technologies in society if we let industrial problems guide the development of new THz technologies at research institutions.

To test this hypothesis, we established the THz Innovation Lab at DTU Electro. The work began in 2016, although the lab was only officially named in 2023. In this paper, we present in an anecdotal fashion how we have developed a new class of THz detectors and brought them to market thanks to an international collaboration. We also present how we spun out the two first THz companies in Denmark as the basis for a national THz ecosystem. Our aim is to inspire researchers to pursue different commercialization avenues and hereby increase the widespread adoption of THz technologies.

Laboratory setup

At the time of writing, the THz Innovation Lab at DTU Electro hosts 10 researchers, the same number of students, and 3 start-up companies. The objective of the lab is to circumvent the traditional challenge encountered in academia, where technical solutions are often devised without a comprehensive understanding of the magnitude of the problem from a societal perspective. Such situations often amount to nothing because the solution proposed by research is too far from being practically or financially applicable to any known problems. This happens even though the solution might be technically far superior to any existing solutions in the commercial market. On the contrary, in a context where a problem precedes the search for a solution, the specifications for the desired solution are typically predefined, enabling an assessment of its suitability prior to its implementation. This gives researchers a fair chance to propose solutions that are in fact practically and financially applicable within a reasonable time frame, thus allowing the further development of a particular solution. Therefore, the THz Innovation Lab builds upon a growing network of companies willing to share their problems. Researchers and students in the THz Innovation Lab can therefore work in synergy with the industry to apply and further develop THz technologies for real world problems while also actively pursuing commercialization of these technologies.

Learnings

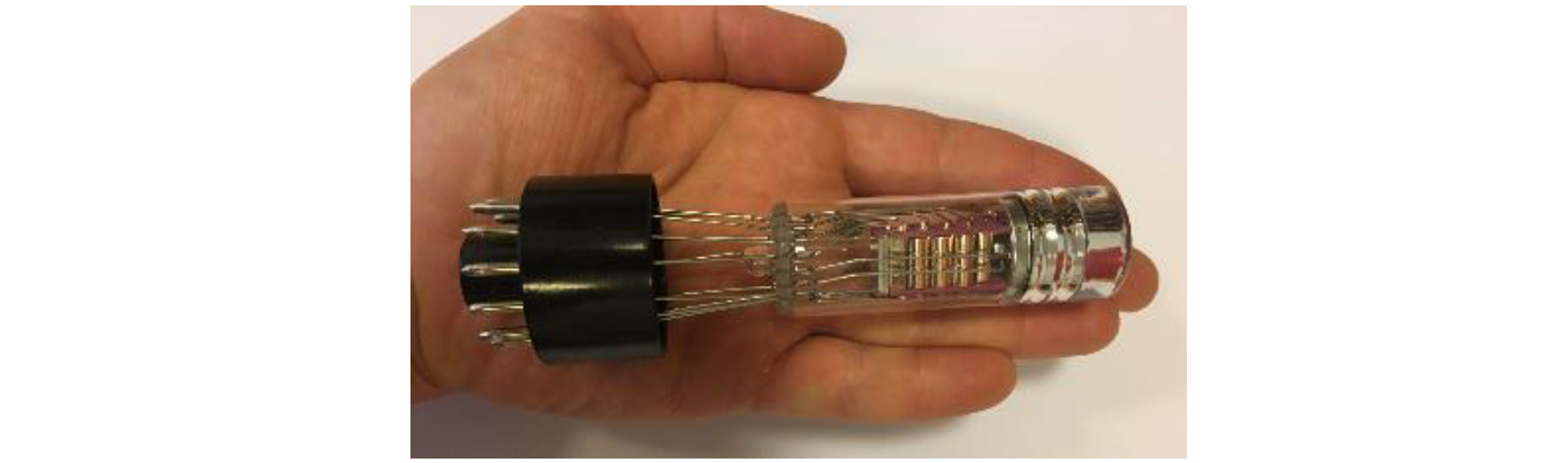

We will now present three examples of how the THz Innovation Lab has participated in novel technology development with concrete industrial applications. The first example is the creation of the THz photomultiplier tube (THz-PMT), shown in Fig. 1. This device consists of a regular PMT for visible light detection, where the photocathode has been altered to be sensitive to infrared and THz radiation using a metasurface. The details about the THz-PMT technology can be found elsewhere [1], but the key questions in the context of this paper are: Why is it practically and financially relevant to develop and market the THz-PMT by the Japanese company Hamamatsu Photonics (HPK), together with DTU Electro? Here are few of many reasons.

Figure 1: Image of a THz-PMT, which is a modification of a normal PMT for visible light detection.

PMTs are mostly handmade and therefore straightforward to customize in production. This has led to more than 100 varieties of PMTs being produced and sold by HPK, for various specialized purposes. Creating a new class of PMTs, wherein a metasurface replaces the conventional photocathode, seamlessly integrates with the current production framework. This does not entail significant capital investments, aligning with the existing production methodology. Moreover, HPK holds a dominant position in the PMT market, which means that the company can afford long product lifecycles without being overtaken by competitors. This in turn leads to an ability to fund early product development with long development timelines, such as the metasurface development for this new class of PMTs. Being invested so early in the development process allows HPK to patent the core functionalities, which subsequently allows academic collaborators like DTU Electro to publish the scientific results instead of keeping them as trade secrets.

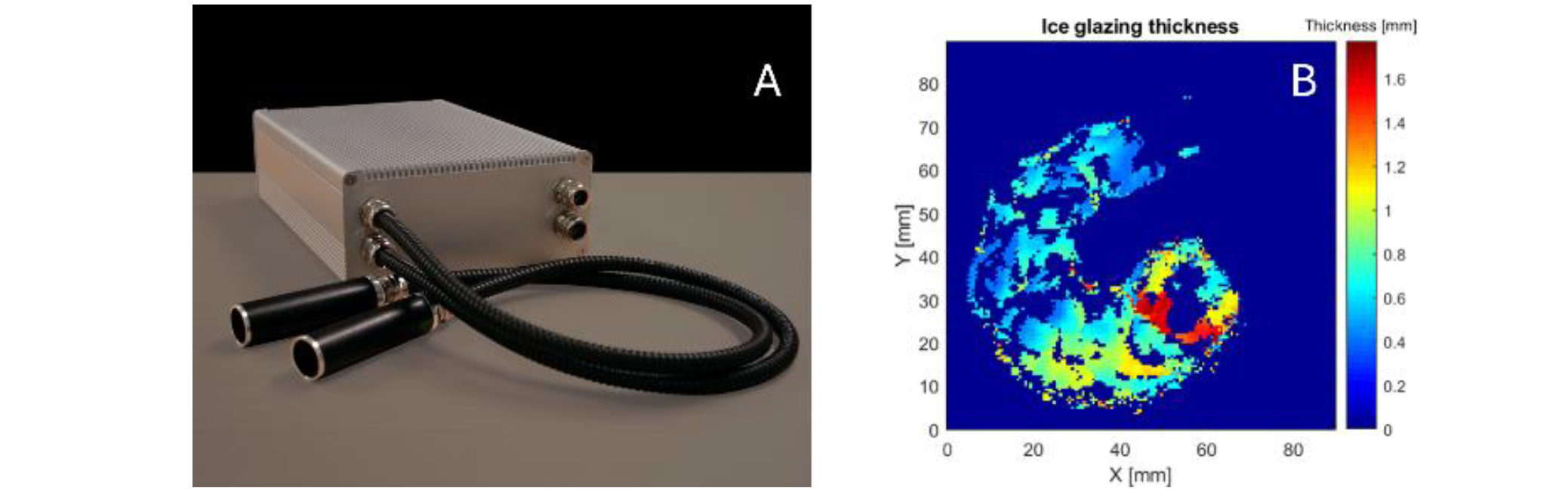

The second example is the creation of the Danish THz company called GLAZE Technologies. The company was in the making for over 5 years in the THz Innovation Lab before it was publicly founded on January 1st, 2023. The company brings a compact and mechanically robust THz spectroscopy platform to market. The architecture of the platform is Cross-Correlation Spectroscopy (THz-CCS) and the details about the technology can be found elsewhere [2]. A THz-CCS system is shown in Fig. 2A. Let us look at why it is practically and financially relevant to bring a new THz spectroscopy technology like this to market.

Figure 2: A) Image of a THz-CCS device aimed at industrial applications. B) Map of the glaze layer thickness on a frozen shrimp.

The THz Innovation Lab started to bring in industrial problems in 2016, with the first problem being: When industrially harvesting cold water shrimps, they are promptly frozen to prolong their shelf life for consumption. In this process, a layer of ice coverage (called the “glaze”) is added around each shrimp. If the glaze layer is too thin, the shrimp’s shelf life is reduced. On the other end, if the layer is too thick, colors and nutrients from the shrimp diffuse into the glaze, which impairs the appearance and nutritional value of the shrimp. Yet, it was not possible in a production setting to determine the thickness of the glaze layer. This was solved in the THz Innovation Lab using THz-TDS in a simple time-of-flight setup, and the result is shown in Fig. 2B. In the end however, the solution never made it to a shrimp production line because a THz-TDS system itself was not practical to use under wet and cold conditions.

The situation did, however, form the basis of further technological development. In the THz Innovation Lab, we applied for a patent on the methodology of measuring the thickness of ice covering frozen foods. With this application, we raised soft funding to build an alternative THz technology to THz-TDS. In particular, we re-created and improved the THz-CCS concept [3] from Morikawa et. al.. In parallel, we found other industry applications with similar system requirements, which we used as story lines when applying for further soft fundings to develop both the THz-CCS system and the applications themselves.

We encountered problems in different industries, including the measurement of road stripe thicknesses, measuring the thickness of eggshells during production, and inspecting underwater coatings on freight vessels, all reducing to a common problem of determining thicknesses of layers in stratified media; always in collaboration with companies that brough in the actual problems. We also partnered with several other institutes at the university to create student projects to contribute to the THz-CCS development in cross-disciplinary ways.

The traction increased so much that we could pull in several senior project leads from large companies, pro bono, to help and advise on how to manage all the activities. When GLAZE Technologies finally spun out, the THz-CCS system was already at a technology readiness level 7 for a list of applications and therefore ready to sell before any investments were made in the company.

Our third example builds on the second: Given that you have a new THz technology ready for the market, who will have a unique advantage of using it? In the THz Innovation Lab, we were aware of this challenge. We therefore decided to pursue the technologically challenging application of using THz radiation to measure blood glucose in humans non-invasively.

The story was clear: The THz-CCS solution is in principle a good candidate for a system architecture that can be scaled to chip size and thus be part of a wearable device, which can become a medical device. By raising funding on this story, we initially started measuring samples of water and sugar using the THz-CCS system. All collected spectroscopic data was analyzed using machine learning models, guided by physical insights. In parallel, we were able to attract top industry talent in machine learning and diabetes to work on the project pro bono for several years, alongside our researchers. After two years, the challenging application of using THz for blood glucose monitoring in vivo turned out to be extremely promising and a new company was formed: GLAZE Life Sciences. The company has today raised private capital and makes up a crucial part of bringing THz technology to wider adoption in the future.

Summary

To further the widespread adoption of THz technology in society, it is necessary to develop both new technologies and applications that match actual problems for companies. In the THz Innovation Lab, we have been successful in creating one new commercial THz detector and two new THz companies in Denmark using this problem-driven approach. We aim to establish an entire THz ecosystem of academia and THz industry in Denmark over the coming years. We also believe that our approach will make a significant contribution to the further advancement of THz science overall.

References

[1] S. J. Lange et. al. “Lightwave-Driven Long-Wavelength Photomultipliers,” Laser Photonics Rev 2024 18, 2470002 (2024)

[2] B. H. Mølvig et. al., “Terahertz Cross-Correlation Spectroscopy and Imaging of Large-Area Graphene”, Sensors 23, 3297 (2023)

[3] O. Morikawa et. al., “A cross-correlation spectroscopy in subterahertz region using an incoherent light source”, Appl. Phys. Lett. 76, 1519 (2000)